IUT Ville d'Avray (France)

2009 participation report and 2010 project presentation

First participation in "all electric" class, first prize!

From the 4th to 6th of June on the Nogaro race track (France), our Institute of Technology (Institut Universitaire de Technologie) of Ville d'Avray, with the participation of students, teachers and technicians, took part in Challenge Educ-Eco, the first French mileage competition which replacedthe European Shell Eco- marathon on this track. For our first competition in the "all electric" class, we won the 1st prize by consuming the equivalent electrical energy of a 2 minute use of a hair-dryer to cover 25 km. We reached the 2nd rank in the group "electricmotor vehicle" ("solar" + "all electric" vehicle), at only 8% more consumed energy, behind the officious long-time-participating "Europeanchampions". We were also ranked 9th in the "thermal engine" class.

This 2009 project was a daring challenge : we enrolled 2 classes with only one vehicle, which is why we had to swap the engine (electric motor<-> thermal engine) ; this divided by 2 the time allowed to trials in each class. Hence, we are satisfied with our success with electric propulsion but disappointed with our rank in thermal propulsion, due to a broken free wheel during one of the trials, followed by a makeshift repair. That reduced our capacity for good performance and, with the "help" of the punctually bad weather, prevented us from running all the authorized trials. Nevertheless, the potential was there as it was partly proved by our first performance.

Here, we wish to thank all the people who contributed to this achievement : students, technicians, teachers, consultants as well as the sponsors who supported us and on whom we rely for next year competition.

Pierre Rochelle et Bernard Toupin

Vehicle technical data

- 3-wheel motorized single-seater:

- overall dimensions (L*w*h in meter) and weigth : 2,83*0,78*0,65 , 55kg

Engines, Transmission :

-

Electric brushless motor Dualsky XM6360-CA12 :

-

-24V DC supply (2*12V-12Ah Yuasa batteries)

-

-modified Honda GX35 centrifugal clutch, fitted to the 8mm motor axle

-

-50A continuous rating controller, with 70A of short-time top intensity

-

-1-stage transmission with 11/129 ratio, 8mm pitch chain, chain tensioning at rest done by engine tilting with use of a tensioner

or

- Modified series Honda NPS50 gas engine :

- -4-stroke cycle engine, 50cm3 capacity, 4 valves, modified water cooling, series electronic injection+ignition unit, volumetric compression ratio of 12

- -1-stage transmission with 13/129 ratio, 8mm pitch chain, chain tensioning at rest by engine tilting with a tensioner

- -rear-wheel centrifugal clutch of a series Honda scooter fitted to the crankshaft

Rear axle :

- -Hope hub with 2-pawl free-wheel, softened pawl springs, reduced ratchet-teeth number, left-side drive

- -20" spoked wheels with low-friction ball bearings,

- -1 Magura hydraulic rim brake,

- -low friction tire

Front axle and steering :

-

-steering gear with Jeantaud/Ackermann links geometry, equipped with adjustable ball joints (adjustment of toe in/toe out and steering arm length)

-

-tilting steering column with a false universal-joint, to ease pilot seating and extraction

-

-20" spoked wheels with low-friction ball bearings, Hope hubs with 12mm cantilever axle

-

-2 mechanical disk brakes, 160mm disk diameter

-

-low friction tires

Chassis frames :

- -main chassis made of 1/2" composite board (fibreglass/epoxy skin and aluminium honeycomb), structural fireguard wall made of 1/2" composite board (aluminium skin and aluminium honeycomb)

- -rear chassis made of square aluminium tubes (20mm*20mm), assembled by pasted and riveted plates, + engine support tilting arm and adjustable ball joints

Controls and indicators :

- -1 Magura MTB brake handle for the rear hydraulic brake + 1 brake pedal for the MTB mechanically actuated front brakes (cables and brake balance-lever)

- -2 push buttons : starter, horn -1 in-line potentiometer as "gas handle"

- -1 switch : for ignition "switch on", with a test lamp

- -1 bicycle counter/computer for the display of elapsed time since start, instantaneous speed and covered distance

Other mandatory equipments :

- -12V approved horn with a dedicated battery

- -approved 1kg fire extinguisher

- -approved 5 anchor-point security belt -2 adjustable rear mirrors

non mandatory equipment

- -hands-free VHF/UHF radiotelephone or cellular phone

Round-lined body(2 parts), with a completely removable upper part :

- -lower body shell made of fiberglass and polyester

- -upper body shell made of fiberglass and polyester, with a 1mm polycarbonate glazing

- -for the race, centering pins and elastic bands are used to assemble the 2 body parts

budget and partnership

- Usually we needed a 6000 to 7500€ budget to cover the expenses due to vehicle realization, logistics and university environment fees. This year 2009, as we were unable to machine parts or carry out tests due to i) the heavy rehabilitation works in our workshop and engine lab, as well as ii) our wish to reduce the subcontracting expenses at a minimum, our budget had to be of the order of 5500€ to take part to the Challenge EducEco and largely higher (8500€) if we would have wanted to participate to the European Shell Eco-marathon competition in Lausitz (Germany), for which we were selected. As the Crisis settled down and our time schedule filled up, we limited our participation to the sole Challenge EducEco (in the south of France).

Public partners :

- Génie Thermique et Energie department of the Institute of Technology of Ville d'Avray (IUT Ville d'Avray)

- IUT de Ville d'Avray

- Université Paris-Ouest Nanterre

Private company or local community partners :

-

Ville d'Avray town council

-

Honda France

-

SMPF (mechanical manufacture company)

-

SNR Hope, ...

Individual partners :

-

Louis Fourdan, Dualsky company consultant

2010 projects :

a new vehicle, optimizations, more participations to international races

the year 2009 results incite us to enlarge our goals by planning i) the building of a new vehicle with the background of our past experience (since 1985) and ii) the participations to the European Shell Ecomarathon (Lausitz, Germany) in the "solar vehicle" class and to the Challenge EducEco in the "electric engine" and "thermal engine" classes with, this time, 2 vehicles (the new one and the old one). The optimization of the old one is planned : ideas are already bubbling.

It is obvious that this project will require more resources : both human means and financial means ; we shall be led to ask help to our old partners who, we hope, will put trust in us again, but also new ones, especially in the new technology area. The next budget should be of the order of 10 000€, at a minimum. So as to give more flexibility to the management of our finances and a larger area to our activities, we are creating a dedicated private association.

The vehicle to come

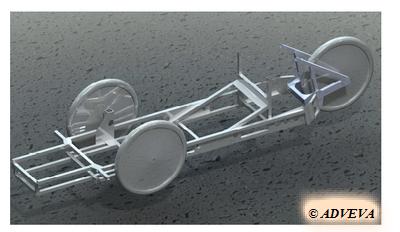

for the year 2010, with the long-time acquired experience and observation of the technical solutions which work well, we want to build a multi-purpose vehicle (able to receive a thermal engine or an electric motor with batteries only or with an added solar cell panel). This one has to be light and with small frontal and lateral areas to minimize the mechanical and aero dynamical frictions. The thermal engine and the electric motor will be optimized and the solar cells will be of superior quality.

The considered solutions are :

-a chassis made of carbon or aluminum square tubes assembled by pasting (and riveting) ; the rear propulsive and directional chassis will be articulated and able to support alternatively the 2 engine types. Having no steering function, the front wheels will present narrower active volumes and, with the same track as before, the projected frontal area of the vehicle will be lower thus allowing a reduced flow friction. Steering will be obtained by the rotation of the complete rear chassis through use of ball-joint articulated rods and levers.

2010 chassis project

-for 2010; the upper body shell will be designed with geometrically developed surfaces, to permit the easy use of 1mm airplane plywood boards, light and robust, and transparent polycarbonate glazing. They will be assembled with fiberglass fabrics and epoxy resin.

...

2010 solar vehicle body project (provisional sketch)

-the wheels will be equipped with wide 20" aluminum (or carbon) rims to fit "high performance" Michelin tires, these rims will be imprisoned between composite-board flanges and centered on hubs equipped with ultra low friction ball bearings.

-the 2 engines will be optimized :

the thermal engine will be a series GX35 Honda engine, largely modified by suppression of useless parts for this particular use or by replacement of series parts by more effective ones (cooling, exhaust line, carburetor, oil shaker, manual starter, piston, ...), especially the carburetion and ignition systems will be replaced by a programmable

Sodemo electronic unit.

the electric motor will be a rewound series Dualsky or Scorpion motor, which already has a good efficiency. Supplementary gains will be added by the use of a homemade programmable controller after the setting of a Hall effect position sensor on the motor axle. The use of a Matra hub-motor will be examined as a second solution.

-the photocell panel will have to be highly efficient and light, at least 17% efficiency and less than 4kg with a mean power of 80W at 30V voltage, and with a 65cm x 150cm maximum panel dimension to be integrated as the rear "roof" of the vehicle.

This will be obtained with space-like solar panels ; it therefore implies a lot of money and a large part of our budget.�

|

| to contact us : |

our Internet site : ecomarathon.iutva.free.fr

association ADVEVA

Pôle Scientifique et Technique de l’Université Paris 10

50, RUE DE SEVRES

92410 VILLE D’AVRAY

e-mail : adveva92@gmail.com

|

Tous les Logos et Marques de ce site sont la propriété de leurs propriétaires respectifs. Les commentaires et les photos sont la propriété de leurs auteurs.

Projet: Éco Marathon IUT Ville d'Avray. Responsable : Xavier Durocher. Webmaster : Bernard Toupin - Mentions légales ©2008

|

|